Compaction is the process of expelling entrapped air from freshly placed concrete and packing the aggregate particles together so as to increase the density of concrete. It is an essential part of any concrete project, as it has a significant impact on the strength, durability, and performance of the finished concrete.

Why is compaction important?

- Increased strength: Compacted concrete is stronger than uncompacted concrete because it has fewer air voids. Air voids weaken concrete by reducing its cross-sectional area and providing pathways for water and chlorides to penetrate.

- Improved durability: Compacted concrete is more durable than uncompacted concrete because it is less susceptible to cracking and spalling. This is because compacted concrete has a more uniform structure and is less likely to contain voids where cracks can initiate.

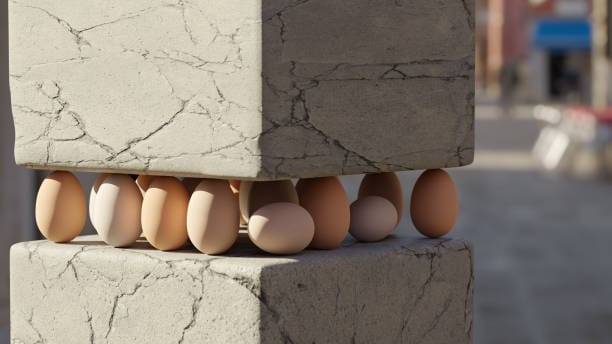

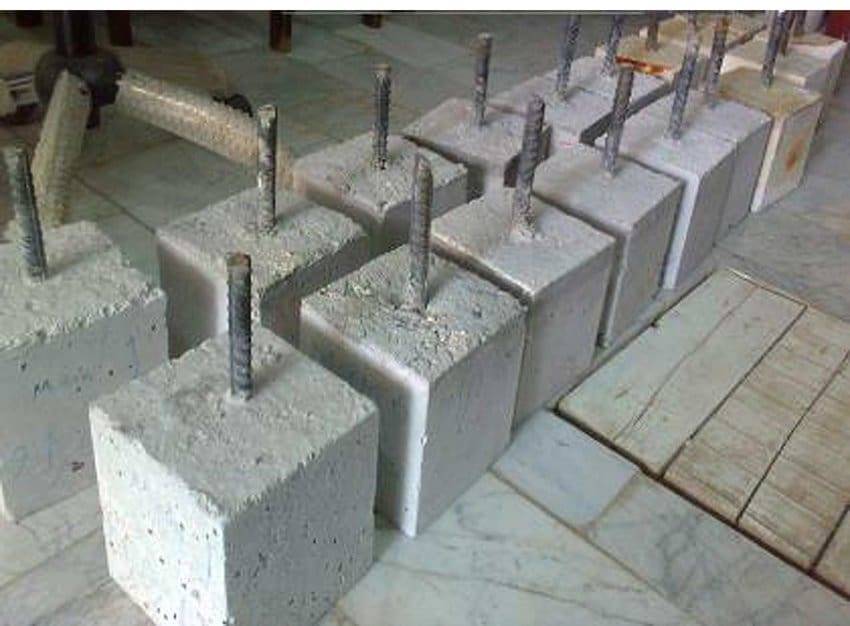

- Better bond with reinforcement: Compacted concrete bonds better with reinforcement than uncompacted concrete. This is because the aggregate particles in compacted concrete are more tightly packed, which provides a better surface for the reinforcement to bond to.

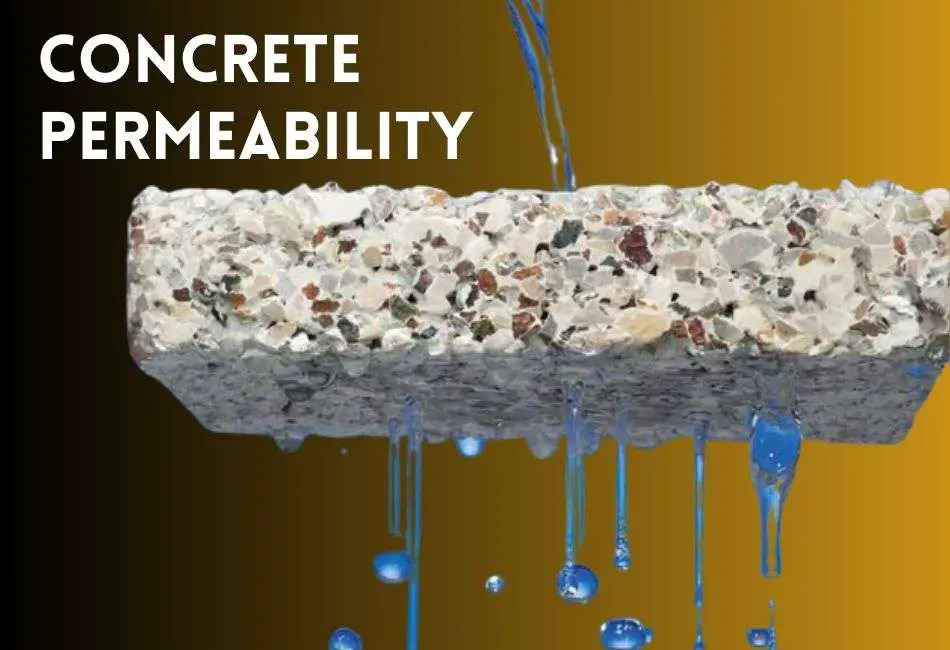

- Reduced permeability: Compacted concrete is less permeable than uncompacted concrete. This is because air voids provide pathways for water and other fluids to penetrate concrete. Reduced permeability makes concrete more resistant to corrosion and staining.

- Smoother surface finish: Compacted concrete has a smoother surface finish than uncompacted concrete. This is because the aggregate particles in compacted concrete are more tightly packed, which reduces the amount of bleeding and segregation.

How to achieve proper compaction

Proper compaction requires the use of the correct equipment and techniques. The most common compaction equipment used for concrete is a vibrating concrete vibrator. Concrete vibrators are used to consolidate the concrete by vibrating the aggregate particles and expelling air voids.

The following techniques should be used to achieve proper compaction:

- Place the concrete in layers: Concrete should be placed in layers that are no more than 12 inches thick. This will allow the vibrator to effectively consolidate the concrete without causing segregation.

- Vibrate the concrete from the bottom up: The vibrator should be inserted into the concrete at the bottom of the layer and then moved upwards. This will help to expel air voids from the concrete and consolidate the aggregate particles.

- Rake the concrete: After the concrete has been vibrated, it should be raked to remove any honeycombing or air voids that may have been missed.

- Strike off the concrete: Once the concrete has been raked, it should be struck off to create a smooth surface finish.

Monitoring compaction

It is important to monitor compaction during the placement of concrete to ensure that the concrete is being compacted to the required density. This can be done using a nuclear gauge or a slump test.

A nuclear gauge measures the density of concrete by emitting gamma rays and measuring the amount of radiation that is backscattered by the concrete. A slump test measures the consistency of concrete by measuring how much it slumps when a cone is removed from it.

Conclusion

Compaction is an essential part of any concrete project. By properly compacting concrete, contractors can produce concrete that is stronger, more durable, and has a better bond with reinforcement. This will result in a finished product that is more resistant to cracking, spalling, corrosion, and staining.