Rebar, or reinforcing bar, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. It is typically made of carbon steel, but other materials such as stainless steel and glass fiber reinforced polymer (GFRP) can also be used.

There are many different types of rebar available, each with its own unique strengths and weaknesses. The type of rebar that is used in a particular project will depend on the specific requirements of the project, such as the load-bearing capacity required, the environment in which the concrete will be exposed, and the budget.

Here is a more detailed overview of some of the most common types of rebar:

- Carbon steel rebar:

This is the most common type of rebar, and it is used in a wide variety of applications, from residential construction to major infrastructure projects. Carbon steel rebar is relatively inexpensive and easy to work with, but it is also susceptible to corrosion. However, there are a number of ways to mitigate corrosion, such as using epoxy-coated rebar or galvanizing the rebar. - Stainless steel rebar:

Stainless steel rebar is more expensive than carbon steel rebar, but it is also more resistant to corrosion. This makes it a good choice for projects where the concrete will be exposed to harsh environments, such as marine or coastal environments, or where corrosion resistance is critical, such as in nuclear power plants. - GFRP rebar:

GFRP rebar is a lightweight and non-corrosive material that is becoming increasingly popular in concrete construction. It is particularly well-suited for projects where weight reduction is important, such as bridge decks and parking garages. GFRP rebar is also resistant to chemicals and alkalis, making it a good choice for projects where the concrete will be exposed to these substances.

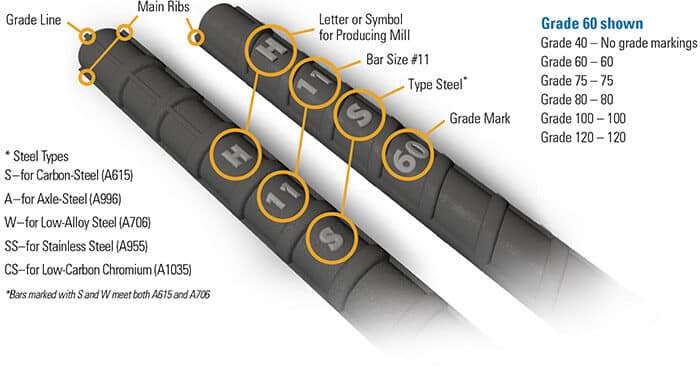

In addition to the different types of rebar, there are also different grades of rebar.

The grade of rebar refers to its yield strength. The higher the yield strength, the stronger the rebar. The most common grades of rebar are 40, 60, and 75.

When choosing a type of rebar for a particular project, it is important to consider the following factors:

- Load-bearing capacity required: The type of rebar that is used will depend on the amount of weight that the concrete will need to support. For example, a project that requires a high load-bearing capacity, such as a bridge deck, will need a stronger type of rebar than a project that requires a lower load-bearing capacity, such as a sidewalk.

- Environment in which the concrete will be exposed: If the concrete will be exposed to a harsh environment, such as a marine or coastal environment, a more corrosion-resistant type of rebar will be needed.

- Budget: The cost of rebar will vary depending on the type and grade of rebar that is used. Carbon steel rebar is the most inexpensive type of rebar, while stainless steel rebar is the most expensive. GFRP rebar falls somewhere in between.

It is always best to consult with a qualified engineer to determine the best type of rebar for your specific project.

Here are some additional things to consider when choosing rebar:

- Diameter: The diameter of the rebar will affect its strength and stiffness. Larger diameter rebar is stronger and stiffer than smaller diameter rebar.

- Length: The length of the rebar will depend on the size and shape of the concrete structure. Rebar can be purchased in a variety of lengths, or it can be cut to size on-site.

- Ribbing: The rebar is typically ribbed to increase the bond between the rebar and the concrete. The ribbing also helps to distribute the load more evenly throughout the concrete member.

Once you have chosen the right type of rebar for your project, it is important to install it correctly. Rebar must be properly spaced and anchored in order to be effective. It is also important to protect the rebar from corrosion. This can be done by using epoxy-coated rebar, galvanizing the rebar, or by providing adequate concrete cover.

So, in conclusion, Rebar is an essential component of reinforced concrete. It provides the concrete with the additional strength and stiffness it needs to withstand tension and other forces. There are many different types of rebar available, each with its own unique strengths and weaknesses. The type of rebar that is used in a particular project will depend on the specific requirements of the project, such as the load-bearing capacity required, the environment in which the concrete will be exposed, and the budget.